Wondering if your garage door opener motor is on its last legs before it completely gives up? By recognizing early warning signs like grinding noises, sluggish operation, and intermittent failures, Vancouver homeowners can avoid being trapped with a dead motor and make smart repair versus replacement decisions.

Your garage door opener motor is arguably one of the most hardworking components in your Vancouver home, cycling up and down multiple times daily while battling our unique coastal climate challenges. Unlike homeowners in drier regions, those living in the Vancouver area face accelerated motor deterioration due to persistent moisture, salt air corrosion, and temperature fluctuations that can reduce typical motor lifespan by 20-30 percent. Understanding the subtle early warning signs of motor failure—from unusual grinding sounds to that telltale burning smell—can save you from being stranded outside your garage on a rainy Vancouver evening. The decision between spending $200-500 on motor repairs versus investing $800-1500 in a complete replacement involves more than just upfront costs; it requires evaluating your system’s age, overall condition, and Vancouver’s harsh environmental impact on garage door components.

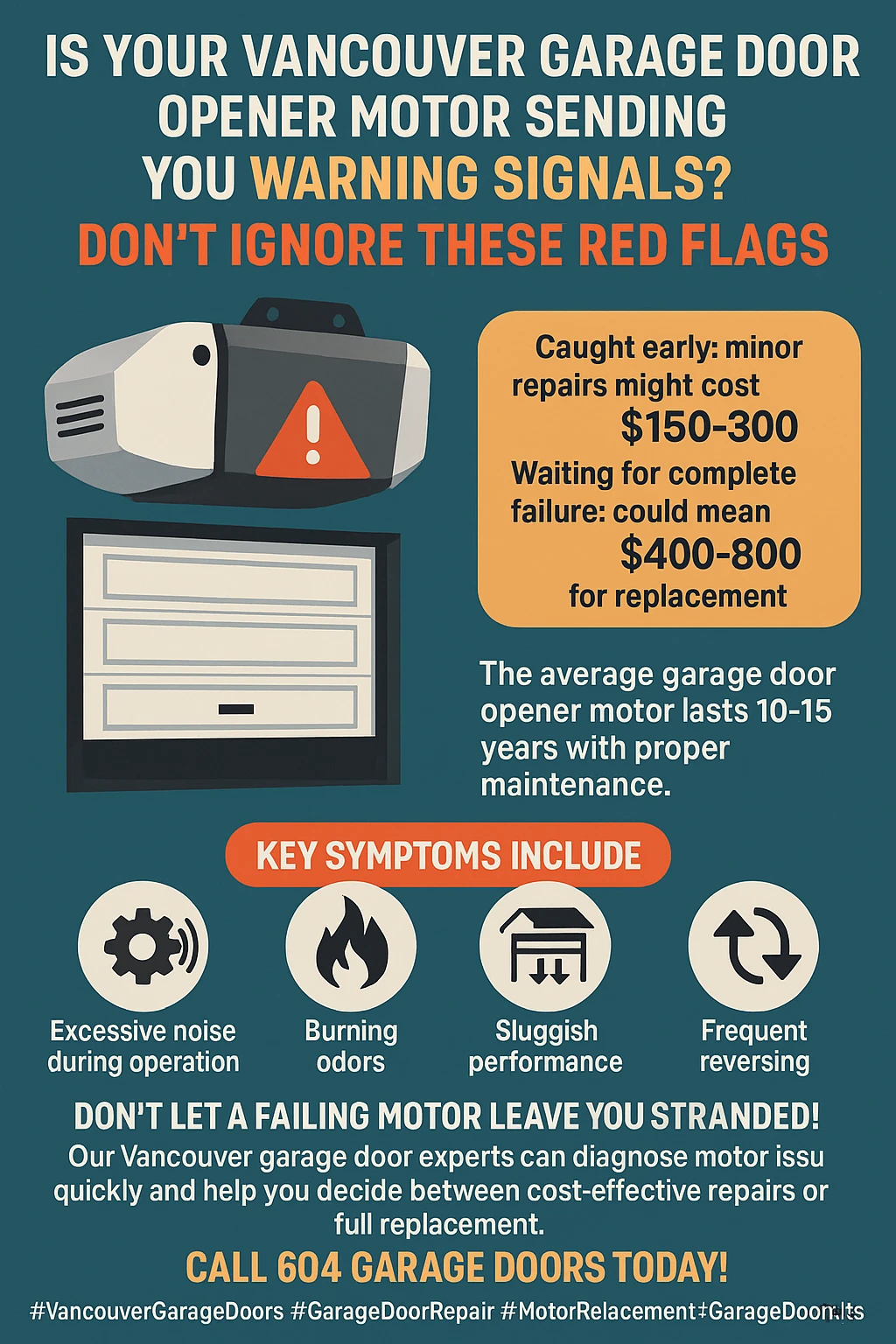

Most Vancouver homeowners don’t think about their garage door opener until something goes wrong, but recognizing the difference between normal wear and genuine motor failure can prevent emergency situations and costly mistakes. [IMAGE PLACEHOLDER FOR IMAGE1] The marine climate creates unique failure patterns not found in other regions, where moisture penetration causes capacitor failures years earlier than expected, and salt air corrodes electrical components that would last decades elsewhere. By understanding these Vancouver-specific challenges and knowing when to call professionals versus attempting DIY troubleshooting, you can maximize your system’s reliability while making informed financial decisions about repairs and upgrades.

Key Outtakes:

- Vancouver’s marine climate reduces typical garage door motor lifespan from 10-15 years to 7-12 years due to moisture and salt air exposure

- Early warning signs include grinding noises, motor humming without door movement, sluggish operation, intermittent failures, and burning smells

- Motor repair costs range from $100-500 while complete replacement costs $600-1500, with replacement being more cost-effective for systems over 10-12 years old

- Preventive maintenance can extend motor lifespan by 30-50 percent and prevent 70-80 percent of emergency failures

- Professional diagnosis is essential for electrical components, springs, and cables—DIY repairs can be dangerous and potentially deadly

Understanding Your Garage Door Motor’s Critical Warning Signs

The first and most obvious sign that your Vancouver garage door opener motor is beginning to fail is the emergence of unusual or increasingly loud noises during normal operation. These sounds—whether grinding, squealing, buzzing, humming, or clicking—indicate that internal components are wearing out, gears are becoming misaligned, or bearings are failing within the motor assembly. What makes this particularly important for Vancouver homeowners is that moisture penetration into the motor housing accelerates these wear patterns, causing grinding or squealing sounds as humidity affects gears and bearings even before electrical components begin to fail. The sound of a humming motor that produces no door movement is especially significant, as this often indicates capacitor failure rather than motor failure itself, though both scenarios require immediate professional attention.

When your garage door motor starts making rattling sounds from the chain or belt drive system, this suggests that chain tension has loosened or belt drive components are wearing, which puts additional stress on the motor and can lead to complete system failure if not addressed promptly. In Vancouver’s humid environment, these mechanical components deteriorate faster than in drier climates, making noise changes a more urgent concern. The key distinction to understand is between gradual noise increases over months or years versus sudden loud noises—gradual changes suggest normal aging, while sudden noise changes indicate recent damage requiring immediate attention.

Another critical warning sign is when your garage door operates noticeably more slowly than usual during opening or closing cycles.  This sluggish operation indicates that the motor is losing power capacity or that internal components are wearing, forcing it to work harder to perform the same task it previously handled easily. For Vancouver homeowners, slow operation is particularly concerning because the added resistance from corroded tracks, rusted springs, or moisture-affected components means the motor must work significantly harder than it was designed to, accelerating its deterioration beyond normal wear patterns.

This sluggish operation indicates that the motor is losing power capacity or that internal components are wearing, forcing it to work harder to perform the same task it previously handled easily. For Vancouver homeowners, slow operation is particularly concerning because the added resistance from corroded tracks, rusted springs, or moisture-affected components means the motor must work significantly harder than it was designed to, accelerating its deterioration beyond normal wear patterns.

Intermittent or inconsistent operation—where your garage door works perfectly one moment and fails to respond the next—represents one of the most frustrating but diagnostically valuable symptoms of motor problems. This inconsistent behavior often indicates electrical issues within the motor’s circuit board, failing capacitors that work sporadically, or loose electrical connections that cause intermittent power loss to the motor. In Vancouver’s coastal environment, intermittent operation frequently results from moisture exposure to electrical components, as humidity causes corrosion that may temporarily break and then re-establish electrical contacts, creating unpredictable operation patterns that demand professional diagnosis.

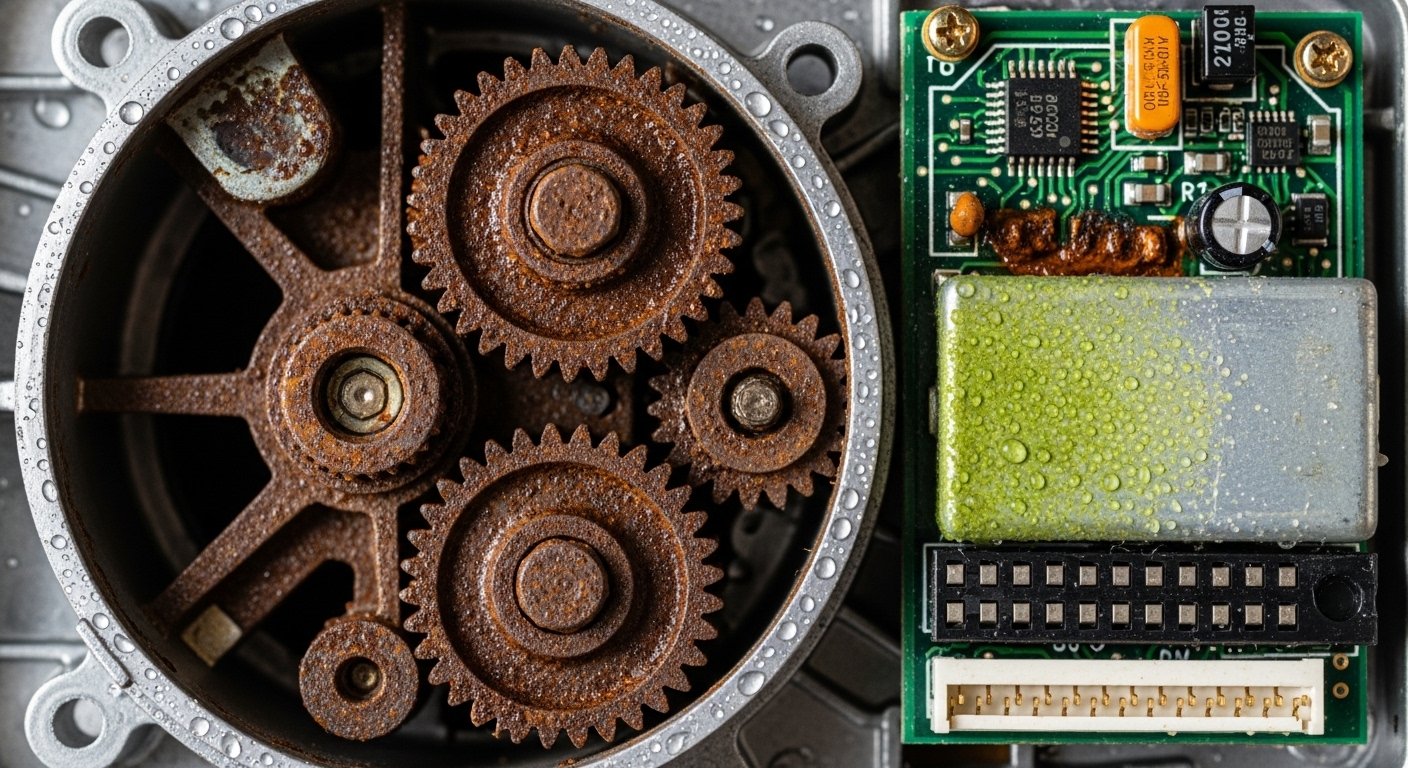

Environmental Factors Unique to Vancouver That Accelerate Motor Failure

Vancouver’s marine climate presents a perfect storm of environmental challenges that significantly impact garage door opener motor longevity compared to systems operating in drier, inland regions. The persistent year-round moisture from rain, fog, and high humidity causes moisture to penetrate motor housings, leading to accelerated corrosion of electrical contacts, circuit board deterioration, and capacitor failure that can occur 2-3 years earlier than in moderate climates. This moisture exposure doesn’t just affect the motor itself—it also causes rust formation on metal springs and hinges, which then require more motor power to move, creating a cascade effect where environmental damage to support systems accelerates motor wear through increased workload.

The salt-laden coastal air presents an additional challenge for Vancouver garage door systems, particularly for homes located near the ocean or other saltwater bodies. Salt particles settle on metal components throughout the garage door system, including springs, tracks, hinges, and the motor housing itself, causing rapid corrosion that increases friction and requires more motor power to overcome. Even the electronic components and circuit boards within the motor are affected by salt air exposure, as salt particles corrode electronic connections and cause electrical faults that lead to premature failure of control systems.

Temperature fluctuations, while not as extreme as other Canadian regions, still create expansion and contraction cycles that affect garage door system alignment and motor performance. When temperatures drop during Vancouver winters, metal components contract slightly, which can misalign tracks and cause doors to operate with increased friction, forcing motors to work harder than normal. Spring tension also decreases in cold weather as metal becomes less flexible, requiring motors to provide additional force to open doors. The contrast between cold mornings and warmer afternoons creates repeated expansion and contraction cycles that eventually cause metal fatigue in springs, hinges, and tracks, all of which increase motor workload and accelerate wear.

Mold and mildew growth represents another Vancouver-specific challenge that affects garage door systems, particularly in poorly ventilated garages where moisture accumulates.  These organisms can develop inside motor housings and on electrical components, causing corrosion and malfunction that wouldn’t occur in drier environments. The combination of organic growth and moisture creates an acidic environment that accelerates metal corrosion and electrical component deterioration, making regular cleaning and ventilation improvement essential preventive measures for Vancouver homeowners.

These organisms can develop inside motor housings and on electrical components, causing corrosion and malfunction that wouldn’t occur in drier environments. The combination of organic growth and moisture creates an acidic environment that accelerates metal corrosion and electrical component deterioration, making regular cleaning and ventilation improvement essential preventive measures for Vancouver homeowners.

Diagnostic Process: Motor Problems vs. System Issues

Before concluding that your garage door motor requires repair or replacement, implementing a systematic troubleshooting approach can save hundreds of dollars by identifying non-motor issues that create motor-like symptoms. Many apparent motor failures are actually power supply problems, sensor misalignments, or support system issues that can be resolved without motor repair. The diagnostic process should begin with verifying basic power supply by confirming the outlet is active, the garage circuit breaker is in the ON position, and the opener unit is plugged in securely—surprisingly, many service calls result from tripped breakers or loose power connections rather than actual motor problems.

The next step involves checking the wall control panel for the lock feature, which when accidentally engaged prevents all remote and manual button operation without affecting the motor itself. This simple oversight accounts for numerous unnecessary service calls where homeowners assume motor failure when the system is simply locked out. Following power and lock verification, examine safety sensors by ensuring proper alignment and confirming no objects are blocking the infrared beam between the photo eyes at the base of the tracks. Clean sensor lenses with a soft cloth and verify that LED lights on both sensors illuminate properly, as dirty or misaligned sensors can prevent door operation entirely.

Testing door balance provides crucial diagnostic information about whether motor symptoms actually result from spring or cable problems rather than true motor failure. Disconnect the opener using the red emergency release cord, then manually lift the door to mid-height and slowly release it—